FROM ECO-FRIENDLY DESIGN TO FINISHED PRODUCT

ALUMINIUM, THE ALL-AROUND MATERIAL

Industrial Design

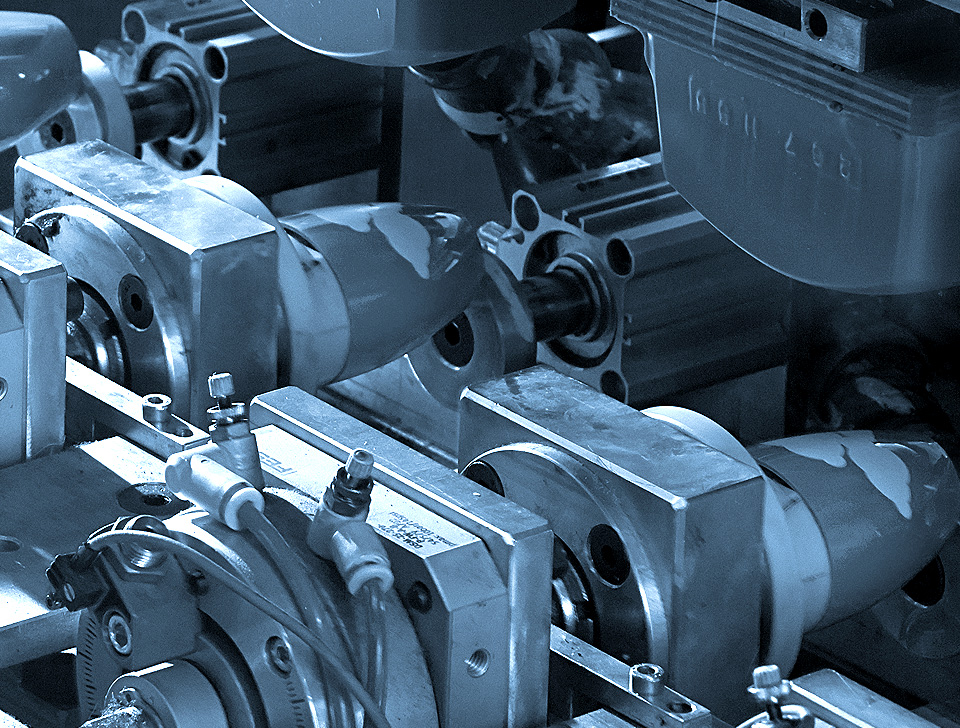

Aluminium embossing, cutting, cold stamping and forming

We own a wide selection of cutting and embossing machines, which enable us to transform the aluminium in simple or complex shapes and to manage the requests of small and huge production batches.

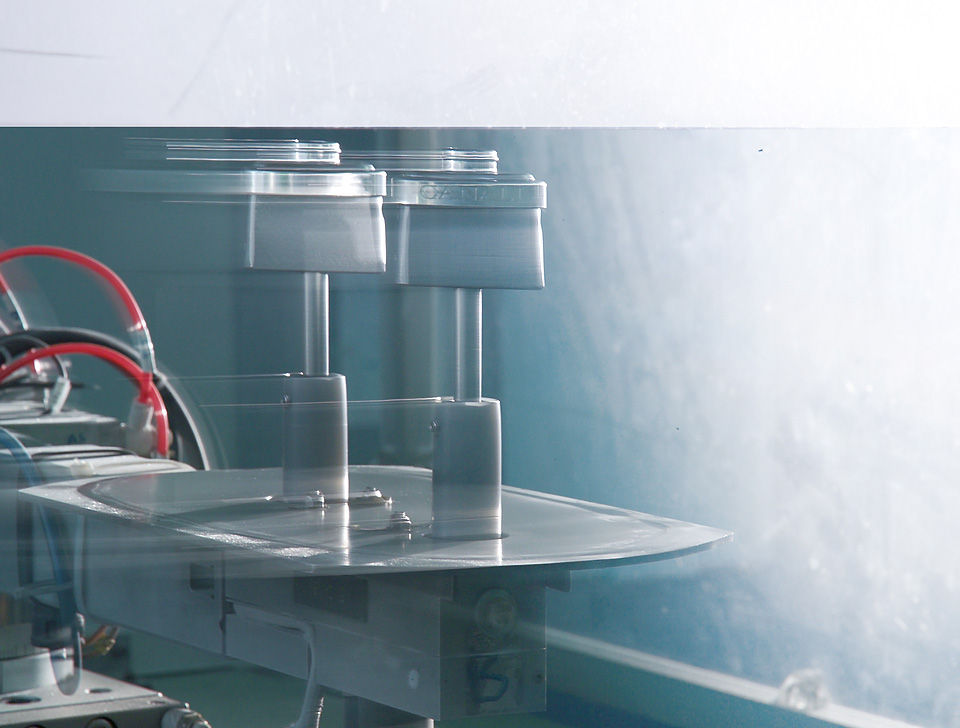

Cleaning, polishing and brushing

The mechanical cleaning process smoothes the surface of aluminium to its maximum shine, achieving a very high quality level. We are equipped with cleaning machines for cylindrical and shaped components.

Anodizing

We are fitted with two anodizing plants that guarantee extreme production flexibility and a wide range of finishes, from the more traditional ones to the more precise shades customization. required by the customer.

Decorations

Logo debossing is one of the most requested technique for refined customizations. Screen-printing, pad printing or hot stamping are some of our decoration techniques. We provide glass and aluminium sublimation decorations, with unlimited colour and shape options for the chosen base.

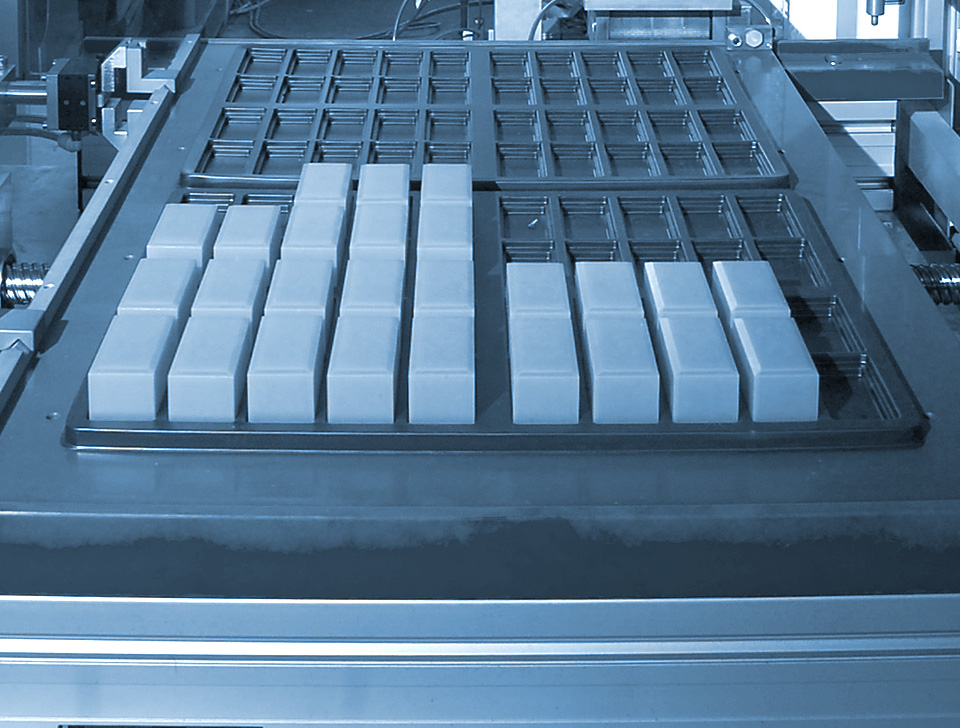

Plastic moulding

We are equipped with injection plastic machines to produce aesthetical and functional components and we evaluate constantly new materials: PP, SAN, ABS, PE.

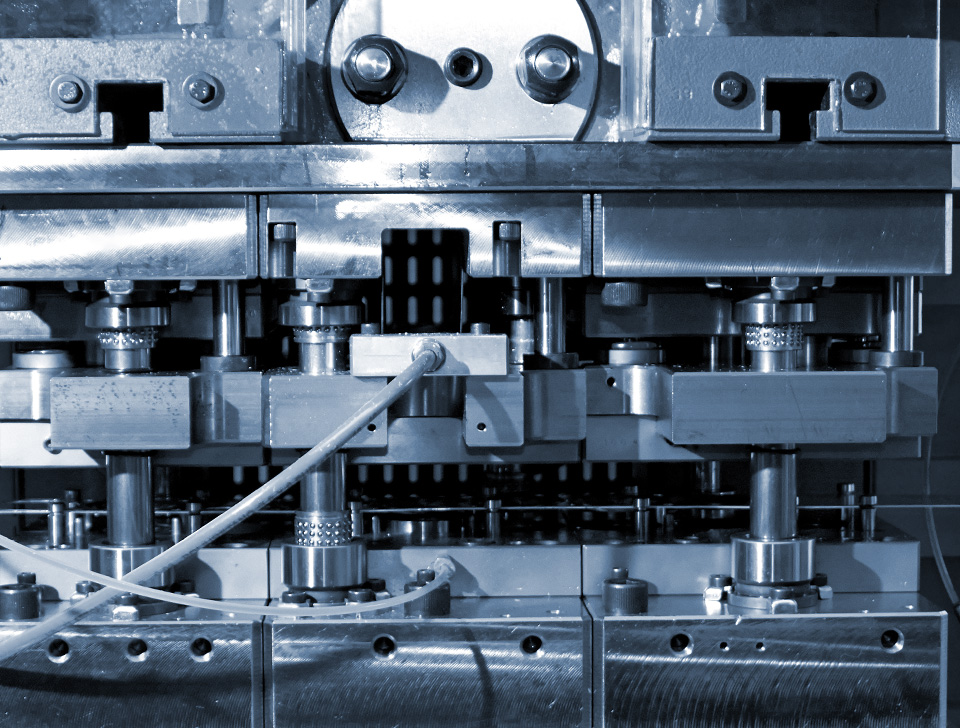

Assembly and gluing

Our assembly line has a wide range of machines which are able to assemble various combinations of materials such as aluminium, plastic and glass.

Our highlights

Updates, ideas and considerations from the packaging world

Luxury and Environment, a winning combination

Inca presents the exclusive recyclable aluminum LIPSTICK, with separable and refillable mechanism, in a particularly virtuous green-solution that does not compromise on luxury.

Luxury 100% recyclable

Luxury 100% recyclableInca offers a luxury vial container, which dresses the glass with a mono-material aluminum shell, 100% recyclable. The refillable packaging is designed to safely and elegantly contain the vial, which is also ideal for travel sizes. Eco-designed,...

Discover our new brand identity

Whether it is the internal process of transformation of aluminum or plastic-based materials, Inca is fully mobilized to provide the best solutions.